So I’ve started experimenting with ways to produce bits for bridles and other hardware. It’s opened up a whole new world of 3D modelling and printing, and its not as hard as you would think, although results are coming out a bit mixed.

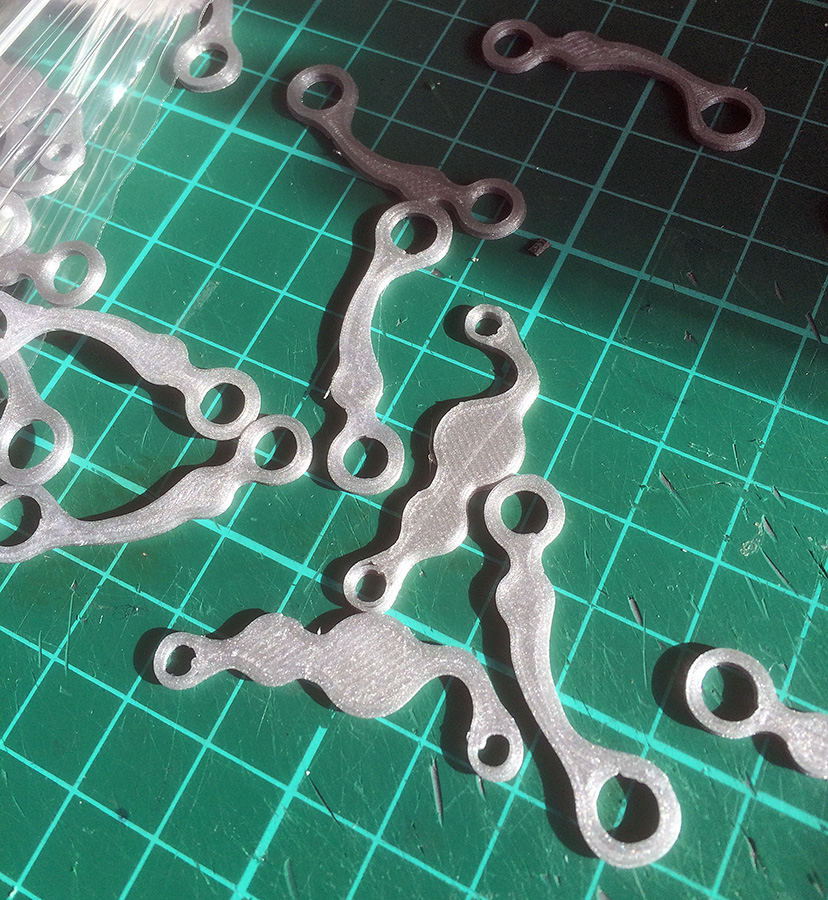

For these first prototypes I used some of my design software, Adobe Illustrator, to produce the outlines of the bits I wanted – there are other cheap/free vector packages out there. Then I used TinkerCad to make them into 3D models and sent them off to be printed. Yep! It was that easy and pretty inexpensive, under £15 a set. The first prototypes were slightly too large for me, despite checking with paper templates first. The second set were smaller but pushing the boundaries of how small you can go on some of the styles. And I quickly found out that a lot of finishing would be required. We are in the realms of acetone baths (didn’t really work for me!), lots of fine sanding and lots of chrome spray layers to get them looking halfway decent. SO… something I am still working on. I have lots of pieces to continue the experiments, but I’m also looking into other processes.

There are many different styles of bits out there for bridles, in the real world. Quite a few of these have been reproduced for the classic and traditional scales, not so many for one sixth scale. Rio Rondo carry a few bits for us, and their other lovely tack items can work across the sizes, which is great. However, its a bit of a pain to get things posted across here to Blighty! A rather long drawn out and expensive business – and lets not even talk about the infamous Royal Mail ‘handling charges’…