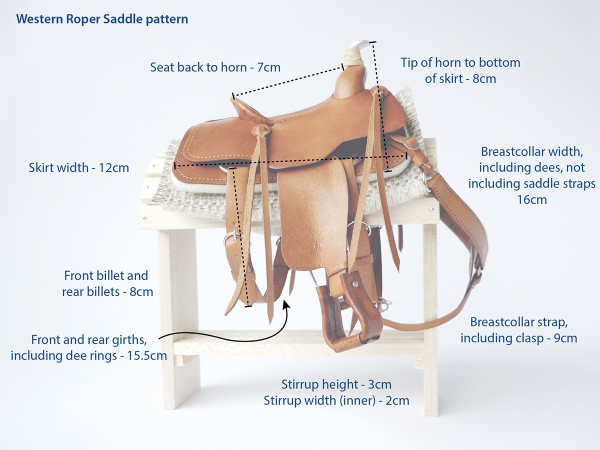

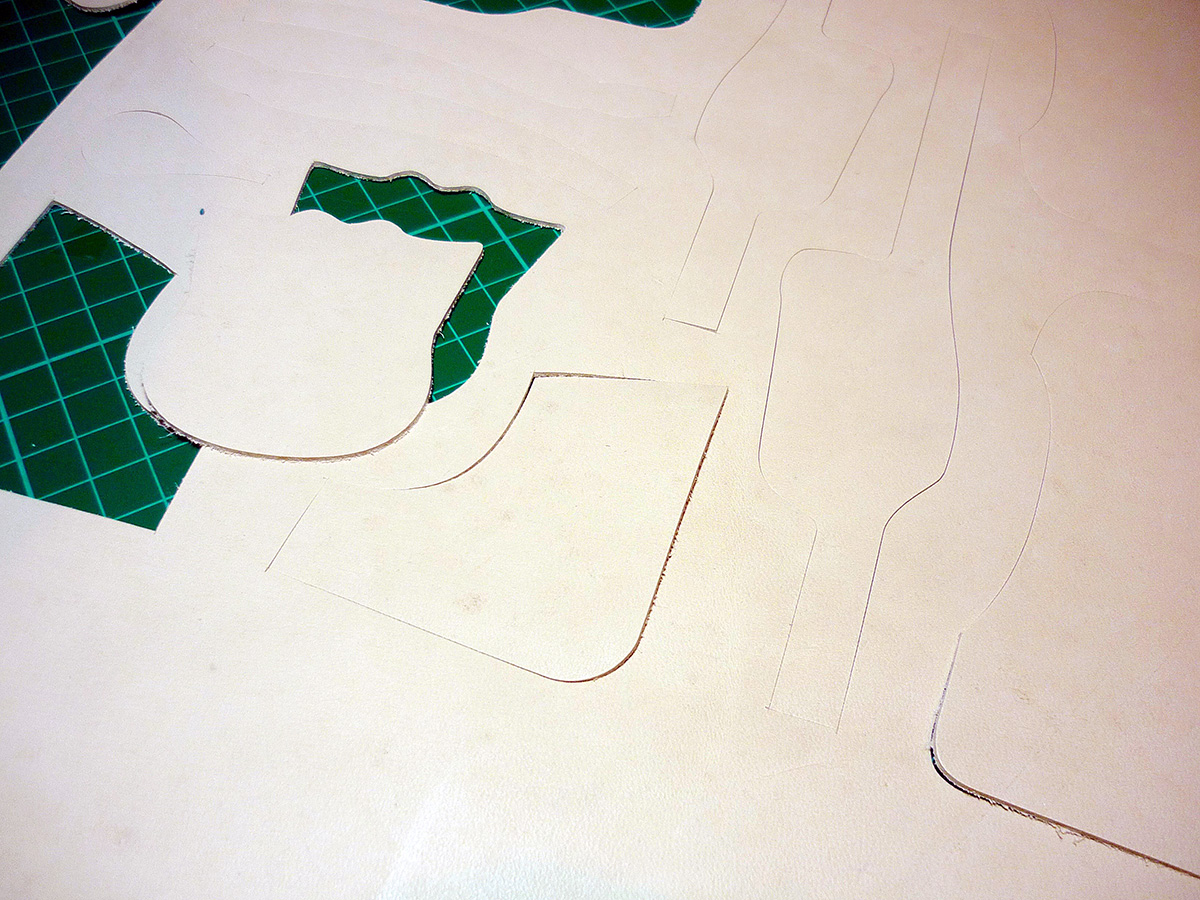

I create saddles for a specific one sixth scale size at the moment. But there are several styles of horses in this category, with more being made. Here are a few useful dimensions for my saddles. I can create the fastenings to fit specific sizes on request, or leave the girth straps without punched holes so you can fit them yourselves. For the experienced hobbyist, my saddles can also be deconstructed careful by removing the conchos and saddle strings to make adjustments to the stirrups under the saddle, then reattaching the conchos.