Working on 1/6 scale saddle pieces needs thin leather in good condition. On the advice from the Tandy leather guys in Manchester, I picked up some extras to improve the quality of my finishing. For the leather itself, Aussie Leather Conditioner, a product to keep it supple and workable and stop it drying out. It is very useful for dry leather, I’m just testing it out, applying some then doing a dye, see if it goes on smoothly. Also Gum Tragacanth and a variety of leather edge burnishers (I’m still trying to find the best ones for thin leather!). But it does make for a really beautiful finish on the edges of the leather.

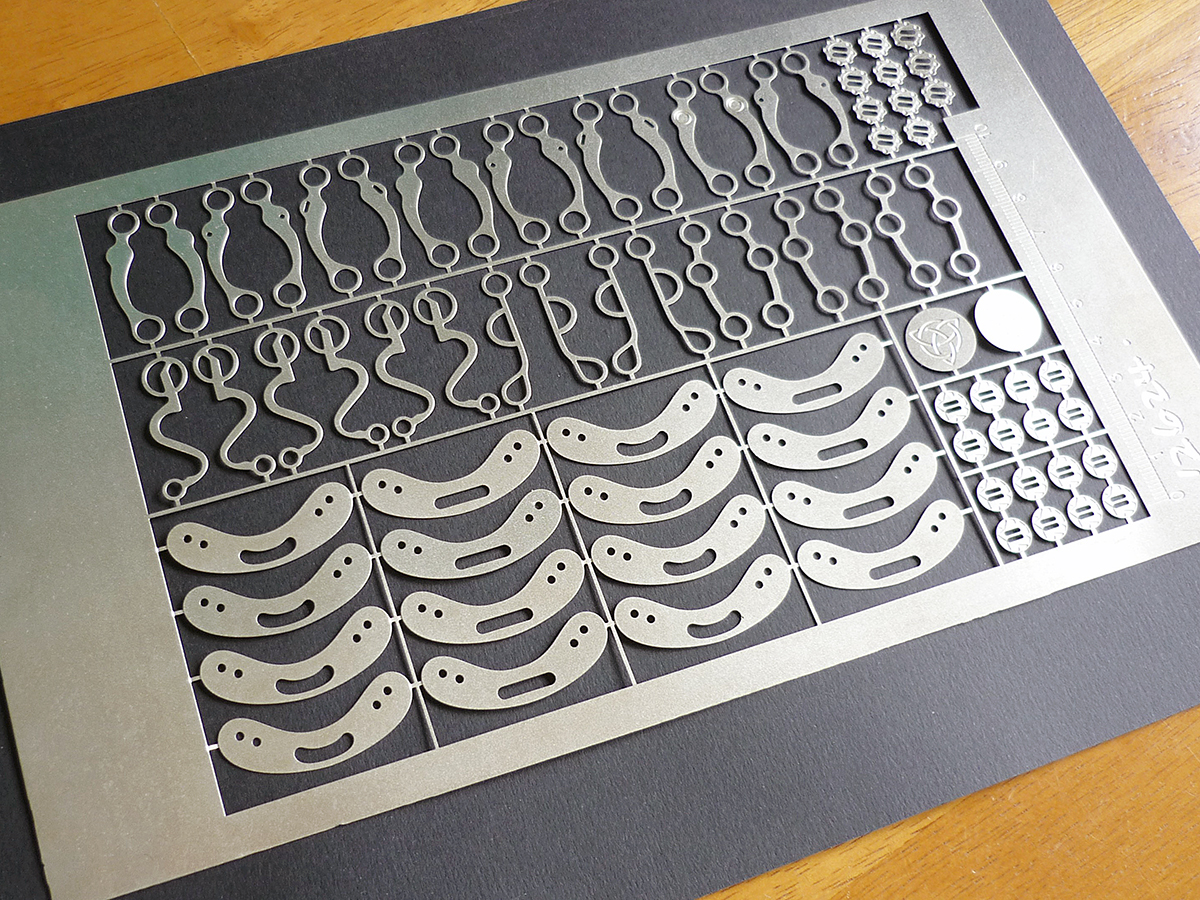

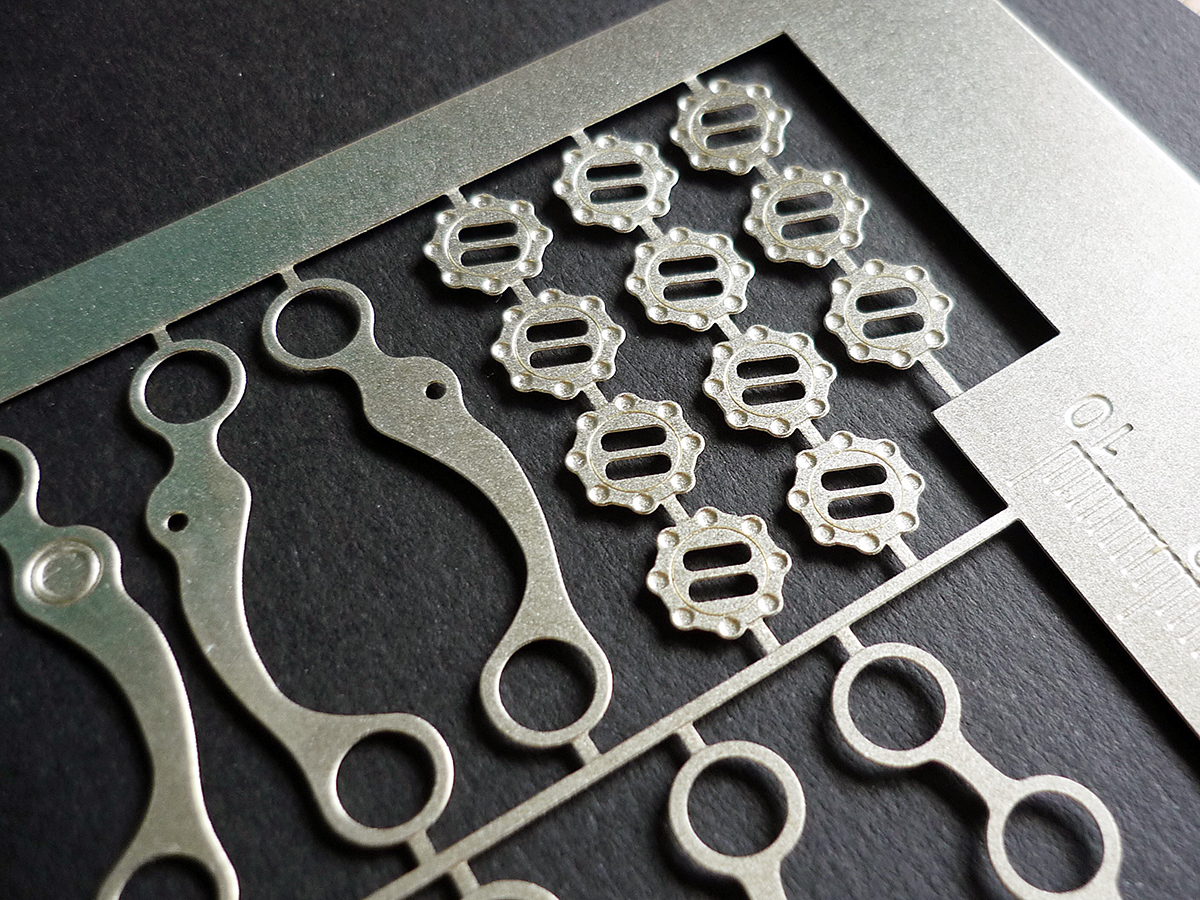

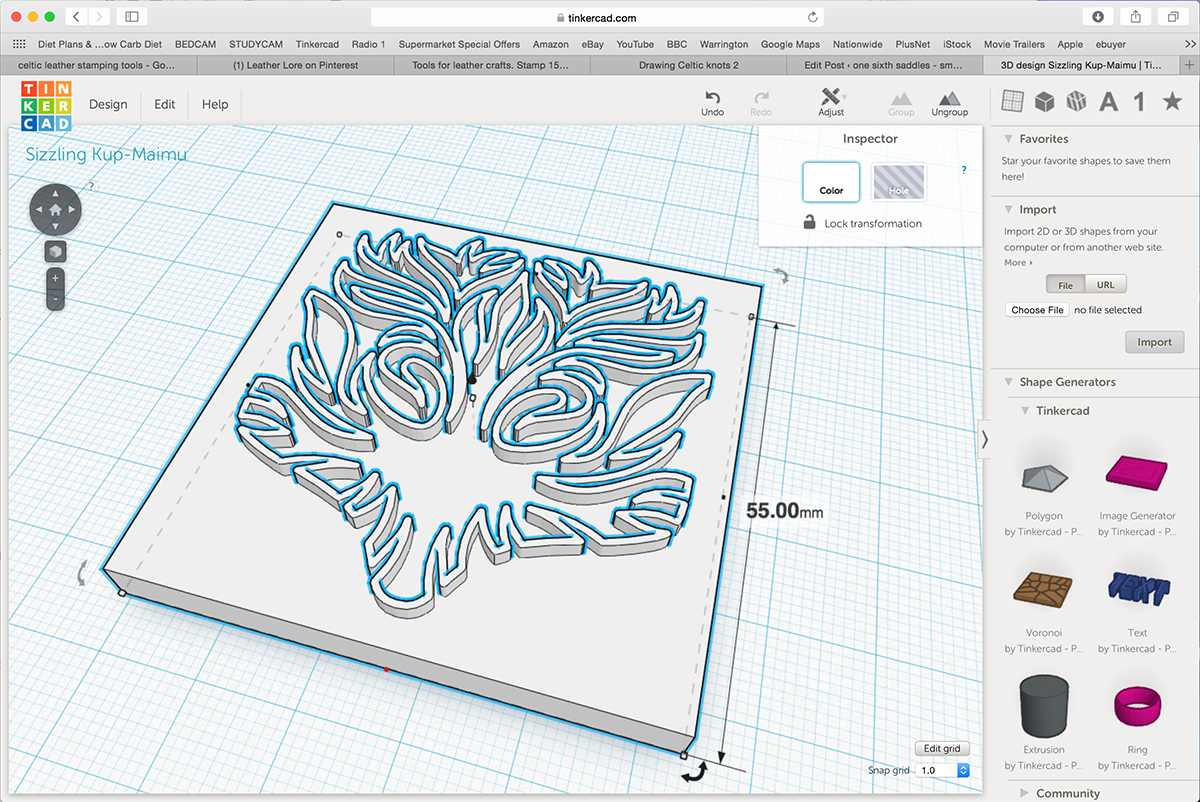

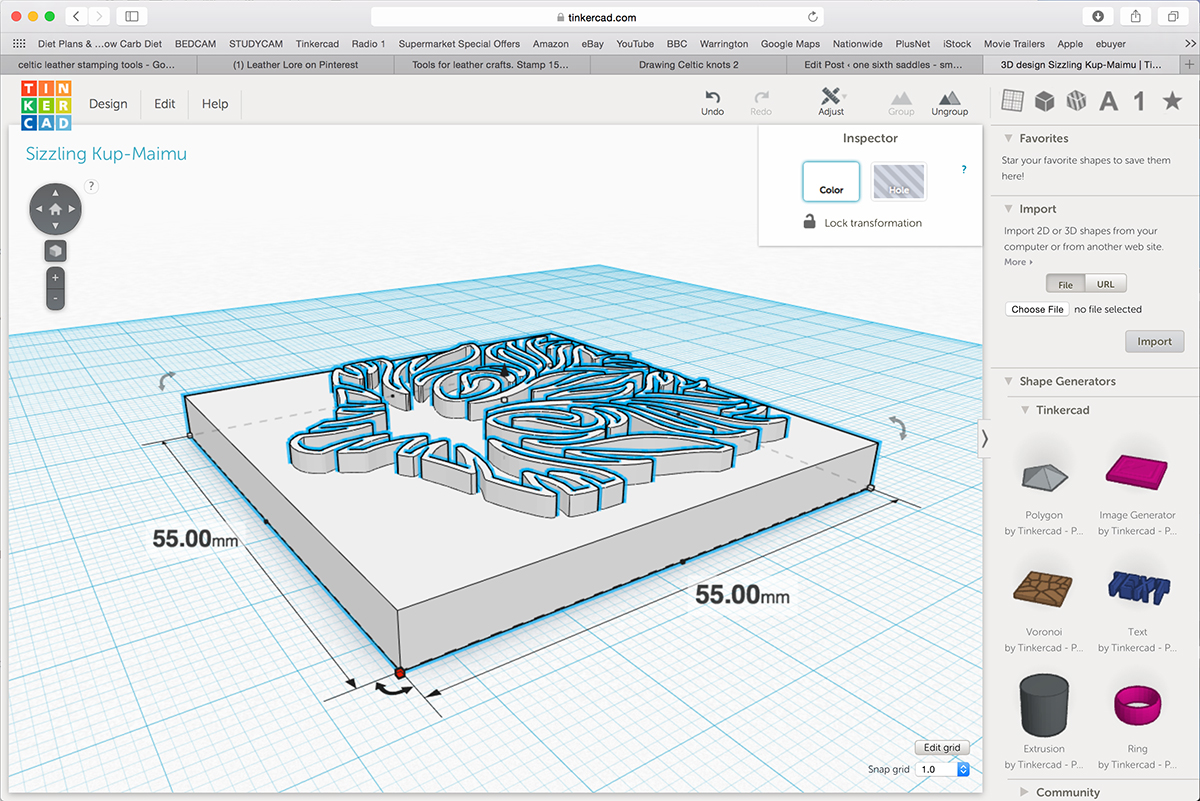

I’ve had a set of Al Stohleman cut saddle pieces in my box for a while now – I’ve been distracted by a somewhat ‘left field’ commission – so I decided to get dyeing last night and get it completed. Today I used the conditioner and edge finishing and the colour has turned out beautifully after being somewhat pale and uninteresting when first dyed. I’ve used 3D stamps on the saddlebags, back jockeys and fenders and I will be using the new photo etched pieces too, it’s all very exciting!