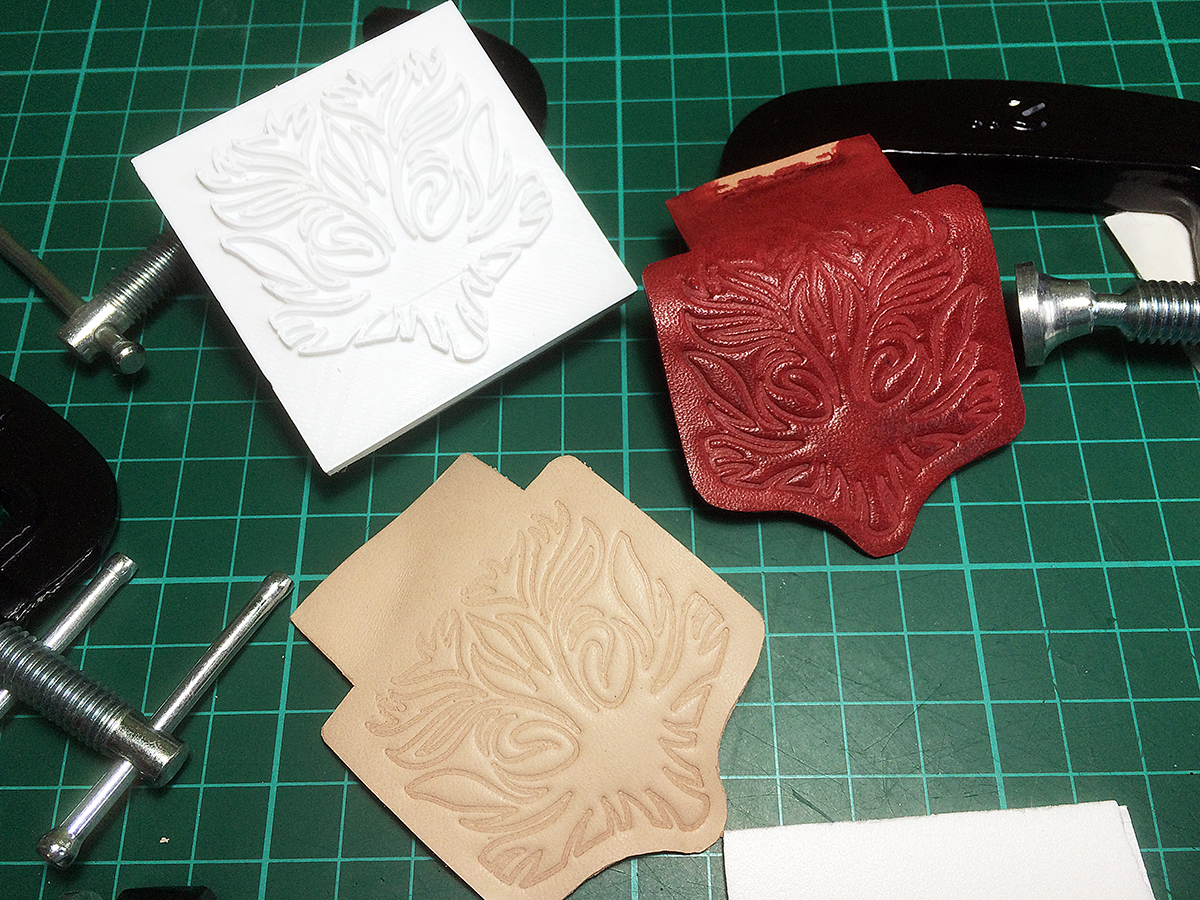

I did go on a leather carving course a couple months back, its a lovely thing to do, working with leather stamps is very satisfying. But it made me think about just how small the carving would need to be to look appropriate at 1/6 scale. So I decided to try another adventure in 3D – and I think it worked amazingly well.

Using my Adobe Illustrator software (again) and one of the handy patterns included I created a saddlebag flap illustration. Sounds easy? Not quite that easy, fiddly and involved some detailed adjustments. And after all that, on the advice of the printers, a little more fiddling! But the finished stamp has been working so well…

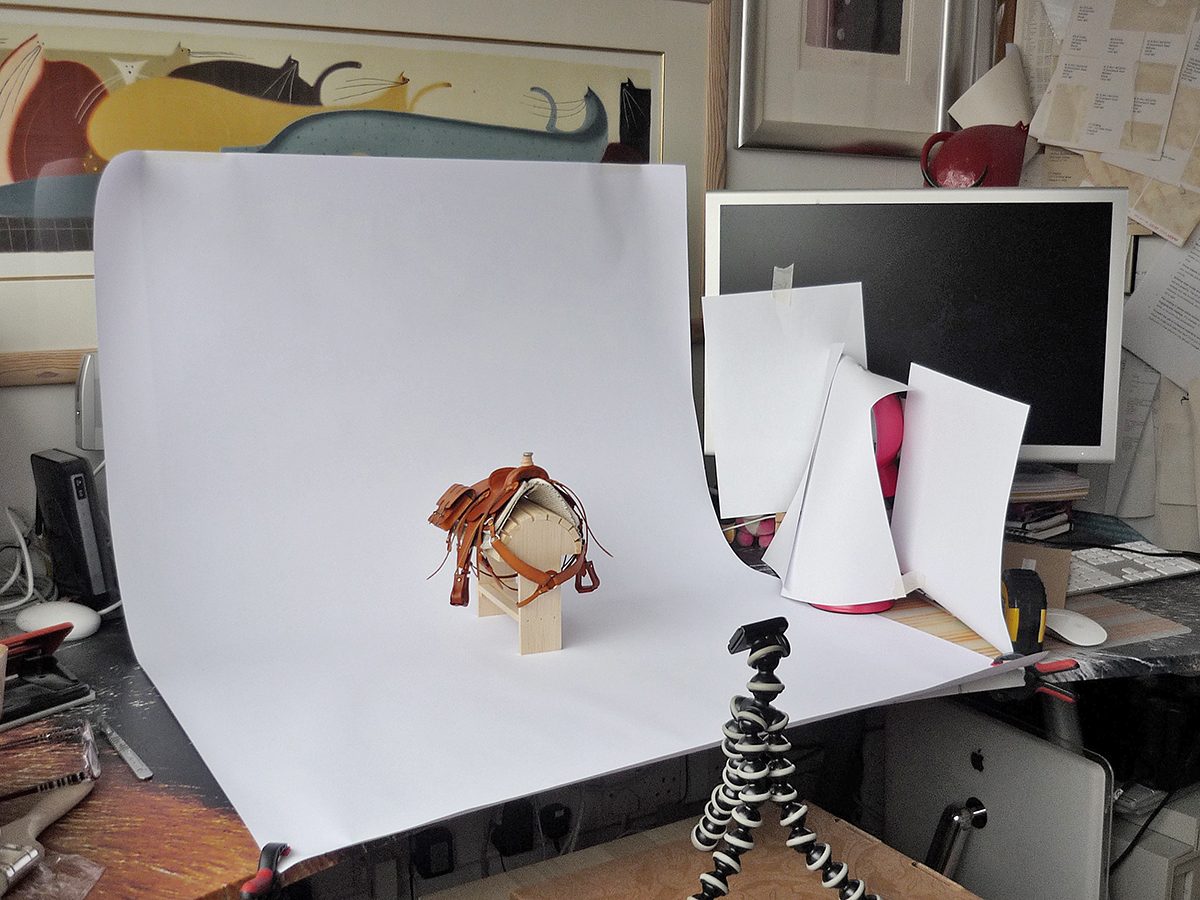

After lots of testing, (sourcing of g clamps) and generally trying out clamping and drying times etc, this is where I’m at. Because its worked so well I have ordered 2 more stamps to complement this one, for the saddlebag connecting strap and front of the bag. I hope to complete a full set of saddlebags very soon…

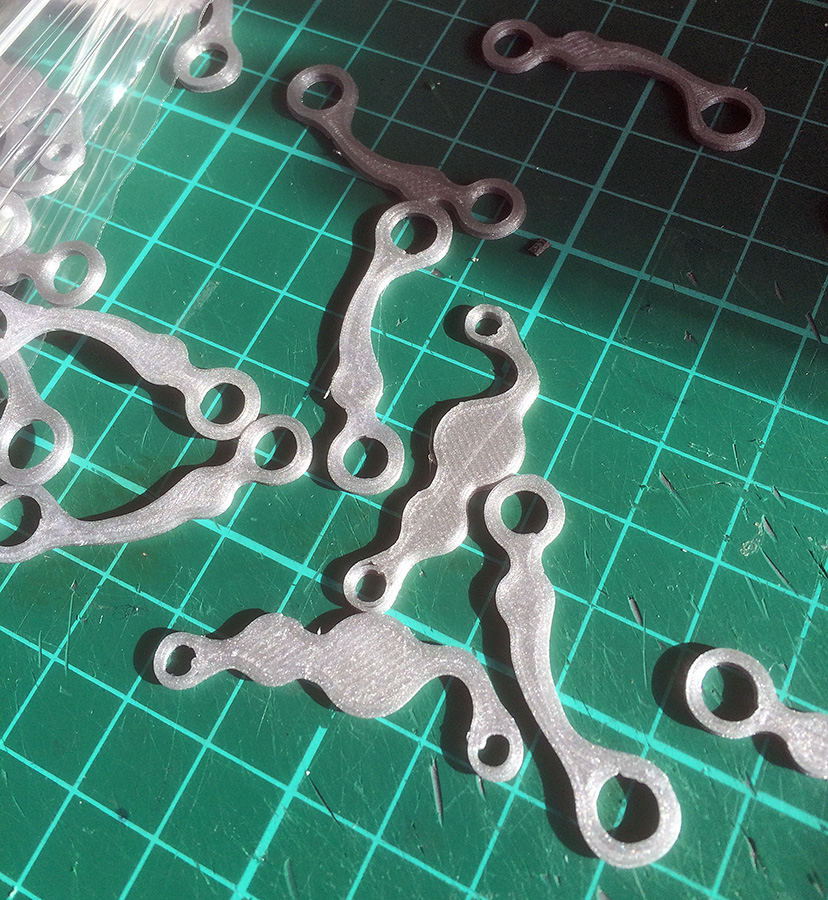

I used TinkerCad to make the 3D models from an outline graphic – www.tinkercad.com

And Hubs to source a 3D printer close to me – www.hubs.com